My 560SEC has been leaking from the power steering and self leveling suspension. In both cases, it is obvious that (at least some) of the leakage is coming from the low pressure hydraulic hoses. It is possible there are additional leaks in the steering, but fixing this obvious one is a good place to start.

I had looked at doing this job a couple of months ago. I quickly saw it was quite fiddly and as I was planning to use the car the next day, I decided to put it off. Once I realized I would be removing the radiator this seemed the perfect time to do the job as there would be a little more room. Unlike the high pressure hoses on the output side of the pump, the low pressure hoses are just standard hoses and are on the input side of the pump.

The first one I did was the power steering hose. I had previously ordered a meter of the Mercedes power steering hose, which should be enough to do 3-4 cars. I’ll need to do this job on my 300SE at some point. Doing this job is a good time to change the power steering oil. Even better, if you have an assistant to do a flush as well. The pump runs at too high a pressure to do it on your own.

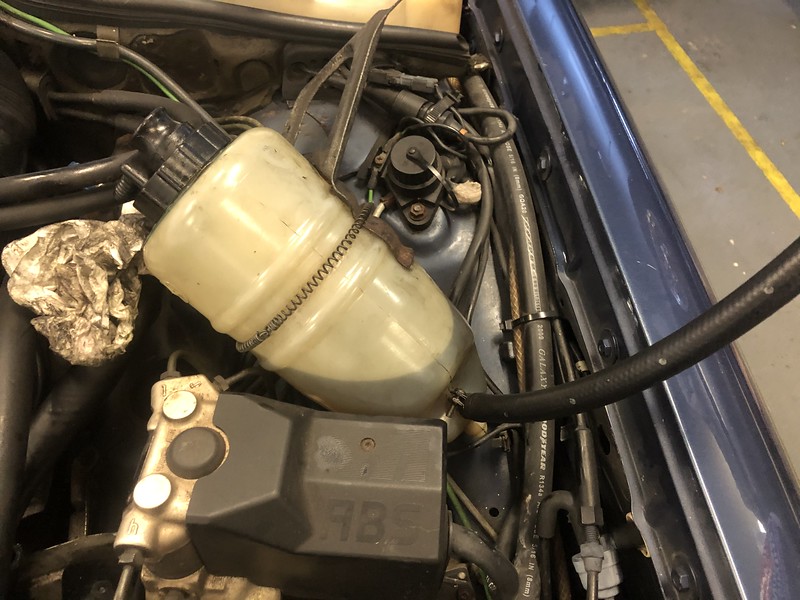

Because of the position of my A/C hose, I found it easier to remove the elbow fitting, as can be seen in the picture below. The flexible hose is quite short and joins up to a hard one in the frame below the P/S pump. The old hose allows for the new one to be cut to the proper size. In the photo below you can also see the hose for the self-leveling rear suspension which is very wet.

My hose was not in horrible condition, but it had been weeping out of the hose material. The new hose and the size required can be seen below. The EPC lists the exact size, and for example the 300SE needs a slightly longer one.

The new hose is quite hard to get on the hard line, and the clamp further tightens it on. I am not expecting any leaks here! I found my battery cable cutter the easiest way to get a good cut on the hose. One of my hose clamps got broken on removal so I will need to replace it later.

The hose for the Self-leveling suspension was in a really bad way. it was leaking quite badly out of the fabric cover, and the hose made a crunching sound, indicating that the inside of the hose had completely failed. I found the easiest way was to clamp off the hose and cut it, so I could remove the reservoir. As I had flushed the system recently, I didn’t plan to evacuate the fluid.

The bracket for the reservoir was a bit crusty and at some point I should do something about it. I don’t think it is supposed to be painted, I think it is supposed to be anodized. I will have to check. The hardest hose clamp is the one that connects to the SLS pump. I needed to find a screwdriver that was the right length and head type. Too long and the fan got in the way. Too short and I could not grip it properly. I think I had nearly all the Phillips head screwdrivers in my toolbox out until I found one that did the job.

I used fuel hose as a replacement as that is basically what the braided hose is. Again, I was able to use the previous hose to determine the required length. It was a bit of a fiddle, but I was able to use my finger to stop the oil coming of the top of the reservoir as I turned it on its side and swapped the hoses out. I then used the hose clamp to stop leakage until I had pushed the other end of the hose onto the hydraulic pump and tightened up the clamp.

I am hopeful that these new hoses will fix some of the worst of the leaks on the SEC. Especially the SLS hose, that one was particularly bad. I will be performing the same jobs on the 300SE at some point.

Leave a Reply