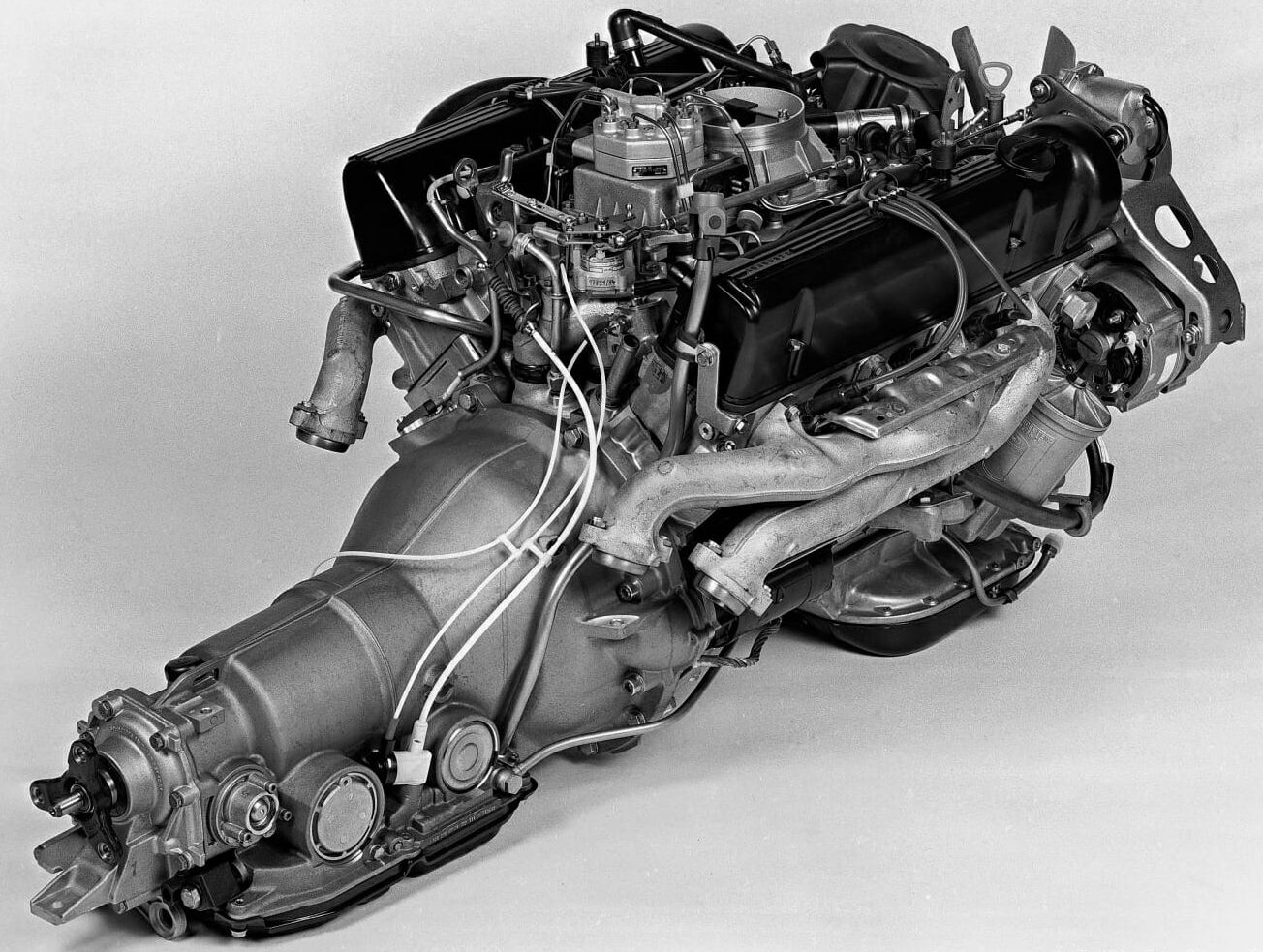

M117 Crank Pully

Back in late January, I went to take my 560SEC out for a drive. I immediately noticed that I had a very odd feeling with the power steering – it was cutting in and out. I opened the bonnet to check the belts and fluid level and saw something rather alarming. The engine was running, but the accessories were hardly moving. They would stop...